The Leader in Panel Bending

First to Market. Over 4,000 Installations. The Largest Selection of Models.

SUPERCHARGE YOUR EFFICIENCY

AND PRODUCTIVITY.

Interested In Learning More?

Let's take your production to the next level.

We will get back to you as soon as possible

Please try again later

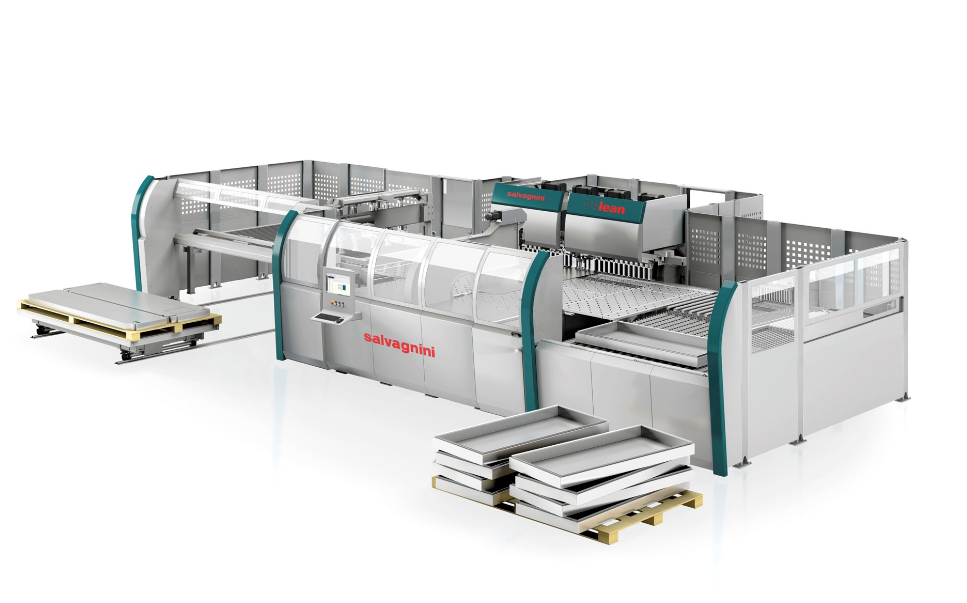

“I am 100% satisfied with our investment, because it’s exactly what we needed: while on average we produced a batch of 40/50 conditioners in 20 days, today we produce a batch of 200 parts in 10 days.”

Fabio Pollastri - Co-Owner of Metalsystem

Blazingly Faster on a Panel Bender

Panel Bender vs Press Brake

Watch a head to head timed comparison of the Panel bender versus the press brake

Improved Efficiency

Enhanced Output

Increased ROI

Enhance every part of your bending process!

When it comes to manufacturing processes, speed, quality, and consistency of production determine the success of your business.

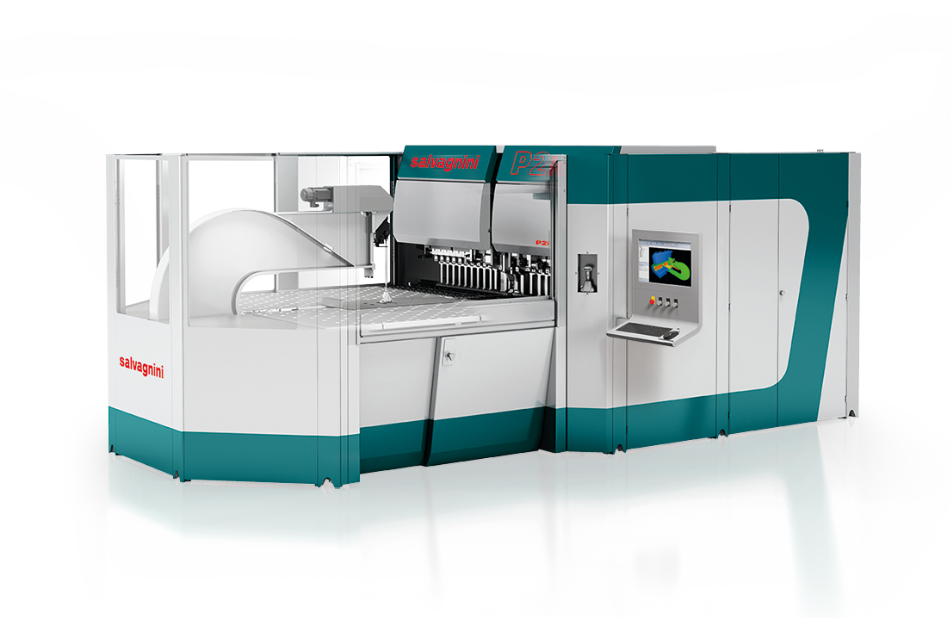

No Retooling

Retooling takes time and reduces productivity. Universal bending tools can be adjusted to different bending lengths and heights without manual intervention

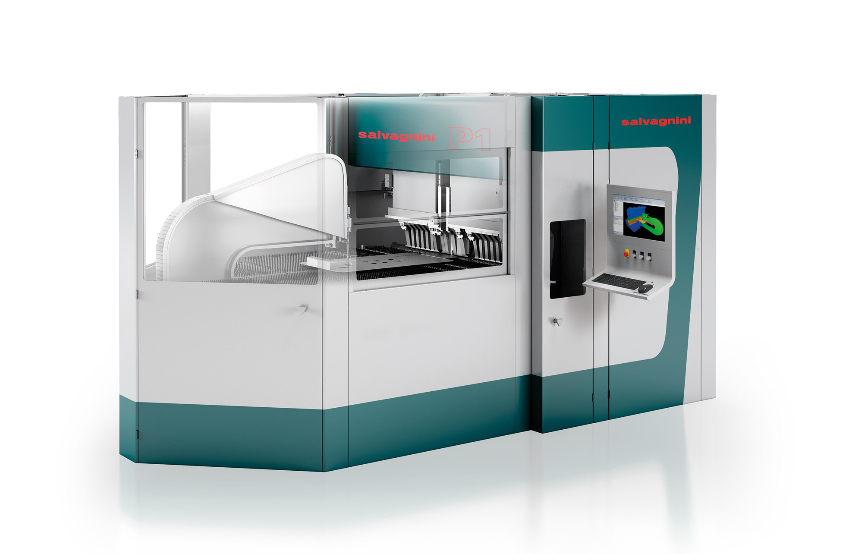

Combining Productivity & Flexibility

Automatic bending and handling cycles enables our panel benders to work at an average of 17 bends per minute.

Zero Set-Up Time

Our panel benders leverage advanced technology to ensure fast and efficient automated tool changeovers, saving time and money

Consistent Quality

Consistency and quality are fundamental to a successful production line. Our panel benders use an adaptive system and proprietary bending formula to manage the movements of the universal tools, ensuring precision, repeatability and quality in every cut.

Connectivity

Benefit from real-time connectivity and coordination with Salvagnini’s OPS. Organize and manage production and create programs and feedback to help eliminate low-value processes.

Meet Sustainability Goals

Integrated sensors, formulas and algorithms help reduce wasteful production processes. Brushless motors help reduce wear and tear on moving parts. By reducing the number of replacement parts, you will reduce maintenance costs while maximizing uptime to boost productivity.

Chat with one of our experienced technicians

to get a better feel for what Salvagnini could do for your production.

Industry-leading customization ensures our panel benders are flexible and adaptable to deal with operating changes while providing precision and consistency in every part.

Salvagnini P4 bending 3 Kit Parts from Max to Min Thickness

Chat with one of our experienced technicians

to get a better feel for what Salvagnini could do for your production.

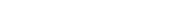

“The compact P2 panel bender was a perfect match for our needs. We could increase our output massively with the smallest possible footprint.”

Werner Terschl - CEO

Schedule Your Discovery Call Today!

Choose a day and time that works best for you and we will give you call.

salvagnini america inc.

27 Bicentennial Court

Hamilton, Ohio 45015 USA

513-874-8284

info@salvagnini.com

Salvagnini America Inc,