FLEXIBLE AUTOMATION

Salvagnini has been designing, producing, and selling flexible systems for sheet metal working for over fifty years, and flexible automation has always been part of the company’s DNA.

Because industry has changed: flexibility and efficiency are crucial requirements for managing increasingly smaller batches, rapid item turnover rate and tight lead times.

In substance: optimizing individual production phases has progressively increased the performance efficiency of machine tools for sheet metal working.

The industrial scenario is moving increasingly towards a substantial reduction in work-in-progress, eliminating the intermediate storage of semi-finished

parts.

Extending the vision to managing and optimizing the process as a whole, obliges us to talk of digital transformation and Industry 4.0, which for the last few years have been some of the hottest industrial topics.

SIGN UP TODAY TO STAY IN THE KNOW OF EVERYTHING THAT SALVAGNINI HAS TO OFFER

Rapid industrial developments of recent years continue to set tough challenges.

Because industry has changed: flexibility and efficiency are crucial requirements for managing increasingly smaller batches, rapid item turnover rate and tight lead times.

We will get back to you as soon as possible

Please try again later

Flexible Automation

Rapid industrial developments of recent years continue to set tough challenges. Because industry has changed: flexibility and efficiency are crucial requirements for managing increasingly smaller batches, rapid item turnover rate and tight lead times.

And it is precisely in this context that automation is attracting more and more attention.

In a nutshell, this concept refers to the use of systems that are able to adapt their operations and, using sensors, control the quality of the jobs produced.

Write your caption hereButton

Write your caption hereButton Write your caption hereButton

Write your caption hereButton Write your caption hereButton

Write your caption hereButton

Automation according to Salvagnini

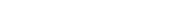

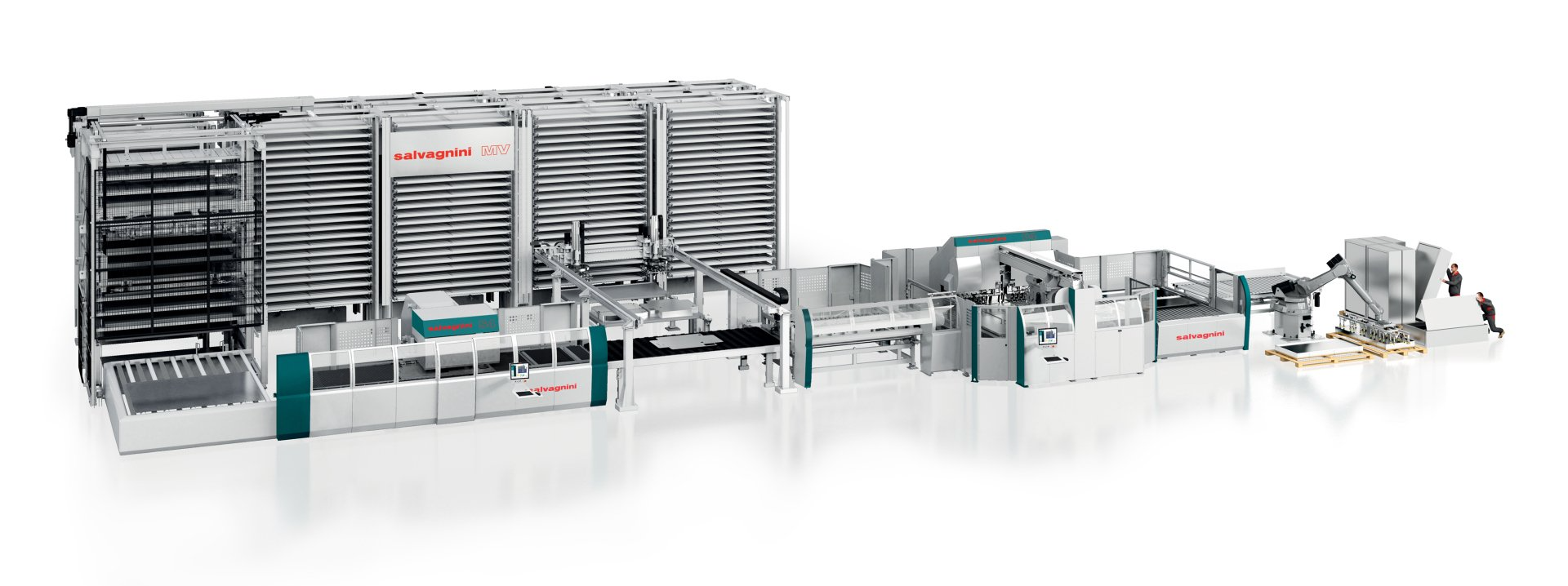

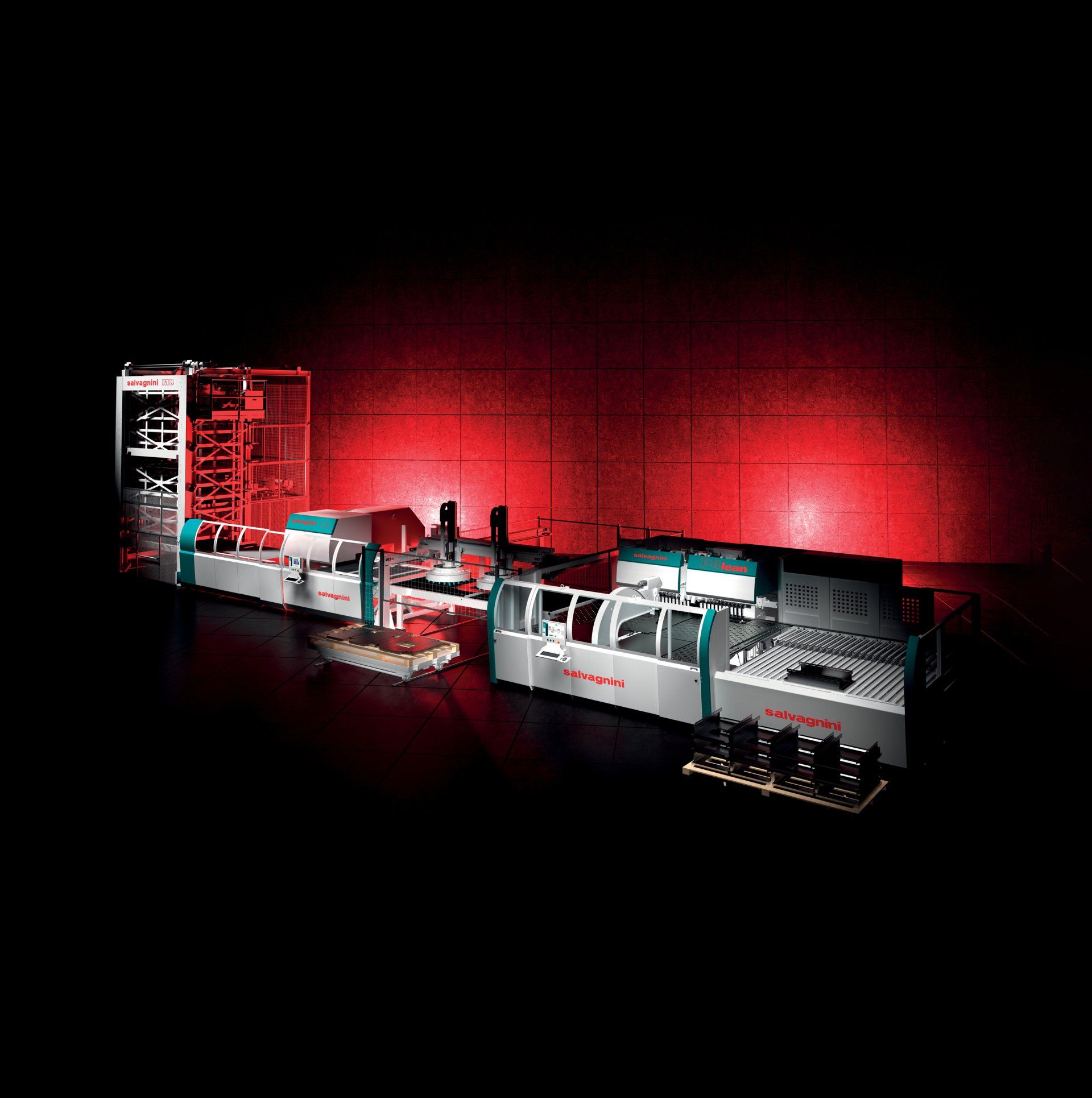

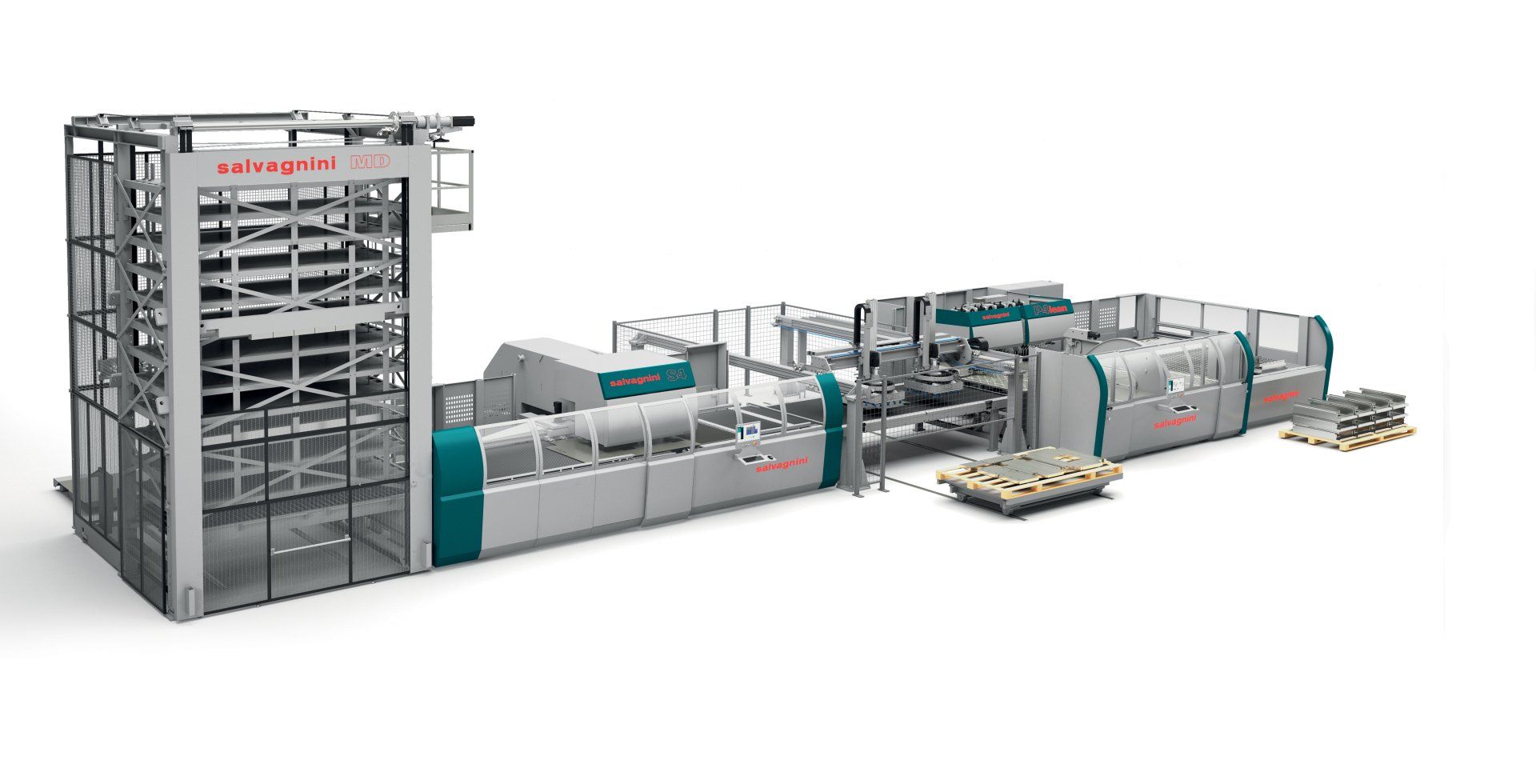

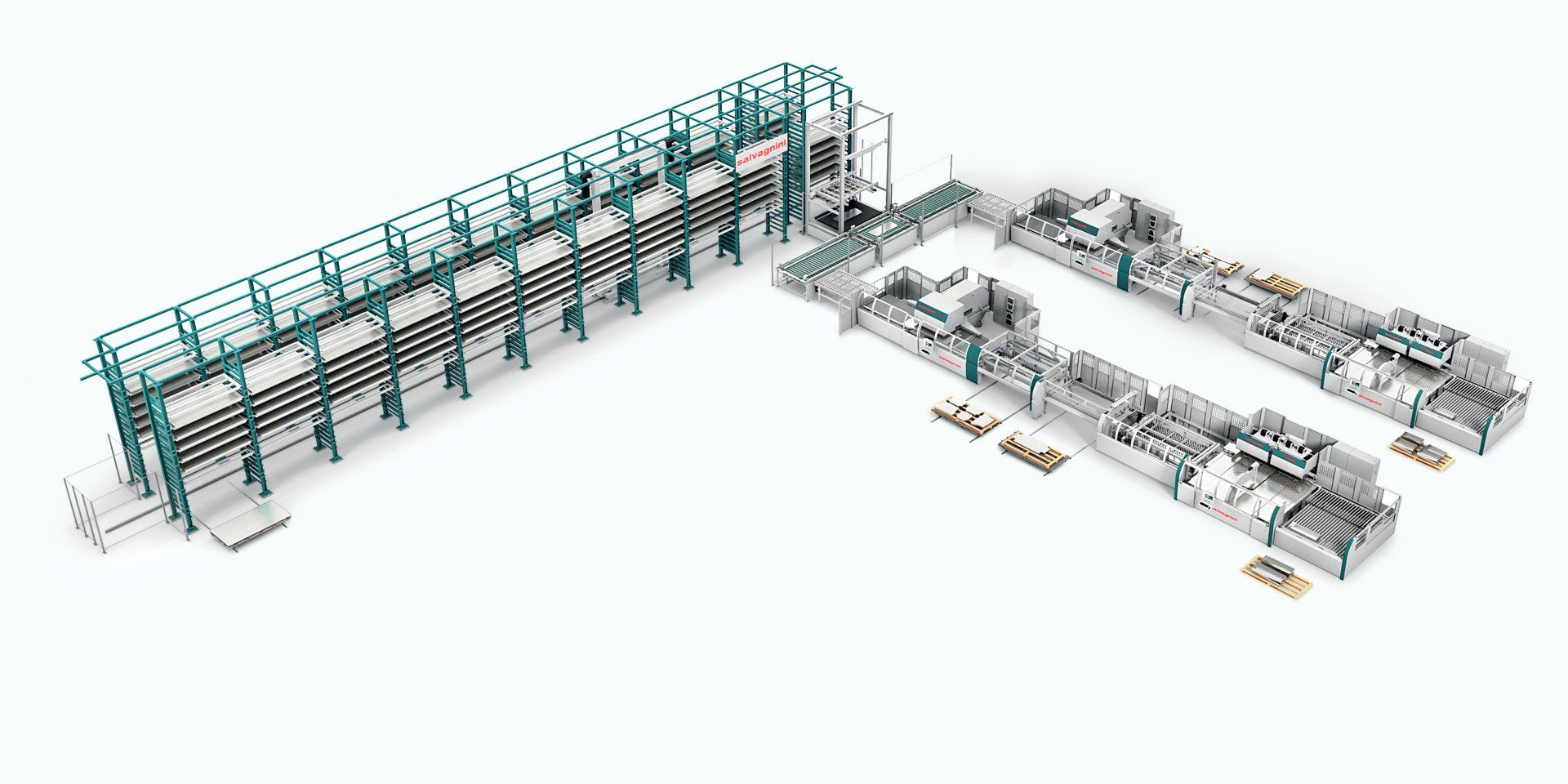

Salvagnini has been designing, producing, and selling flexible systems for sheet metal working for over fifty years, and flexible automation has always been part of the company’s DNA. According to Salvagnini’s vision, flexible automation means transforming packs of sheet metal into a wide variety of products, in a lean environment and with no intervention by the operator, in a progressive production process, using proprietary punching, cutting, bending and panel bending technology.

Automation therefore has an impact on three successive levels:

• the first level is that of the individual production phase, which horizontally exploits the potential of extremely high-performing, autonomous and intelligent systems;

• the second level is that of activities with low added value, which typically occur upstream and downstream of these individual systems, with preparatory and/or connection functions;

• the third level is that of the process which, where appropriately organized, benefits exponentially from the sum of advantages offered by the previous two levels.

In practice, the result of an automated, organized process can exceed the sum of the benefits obtained in each individual activity and by eliminating any redundant intermediate activities. How? Let’s take a detailed look at the production process.

Optimizing individual production phases

We have already mentioned the progressive shift from a make-to-stock strategy, with large batches, towards a lean, make-to-order, just-in-time strategy based on medium and small batches and an increasingly variable production mix. And the industrial scenario is moving increasingly towards a substantial reduction in work-in-progress, eliminating the intermediate storage of semi-finished parts.

To respond to this variability and uncertainty, the market is looking more and more to flexible production systems. Because being competitive today does not merely mean having fast single part production: the challenge lies in production efficiency, understood as the ability to move from one production code to the next with the shortest re-tooling time, whatever the geometric and mechanical characteristics of the metal sheet and the type and number of jobs. These flexible systems are a decisive factor for managing production today, but also for improving quality and reducing lead times and scrap.

Responding to these needs, all Salvagnini solutions are designed to increase the efficiency of the specific production phase. There is no need to remind anyone that, since 1977, the year in which Guido Salvagnini designed and produced the first P4 – Salvagnini has been a byword for panel bending. The panel bender is the machine which more than any other represents the spirit of the Group, precisely because it combines cutting-edge technology with productivity, autonomy, and flexibility. With universal bending tools, the panel bender requires no re-tooling, and machines the whole range of thicknesses and materials, adapting automatically to the size and geometry of the part to be produced, in cycle, without machine downtimes or manual re-tooling. Its high technology allows it to adapt completely autonomously even to the varying mechanical and geometrical characteristics of the sheet metal being machined, as well as to the external environment. Semantically at least, similar characteristics also define the other Salvagnini technologies:

Salvagnini Technologies

Save time

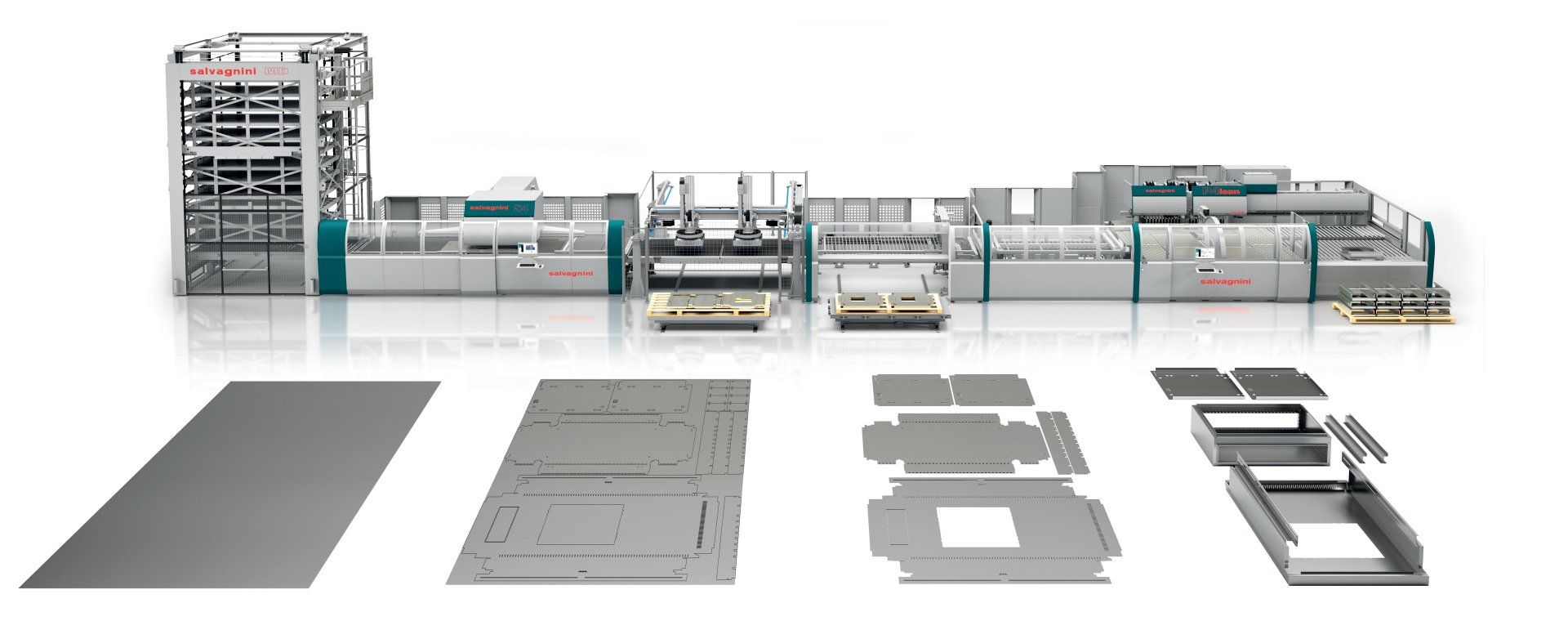

The laser requires no adjustments, as the single-optic cutting head processes all the machinable thicknesses and materials, speeding up production changeovers. Both the process sensors that control and automatically adapt the cutting phases and a number of artificial vision systems that shorten the time taken to perform burdensome activities help to minimize scrap

Multi-Press

The combined punching/shearing and punching/laser machines are equipped with a multi-press head that can hold up to 96 tools which are always available for use, guaranteeing high quality machining with short cycle times without the need for set-ups;

Adaptability

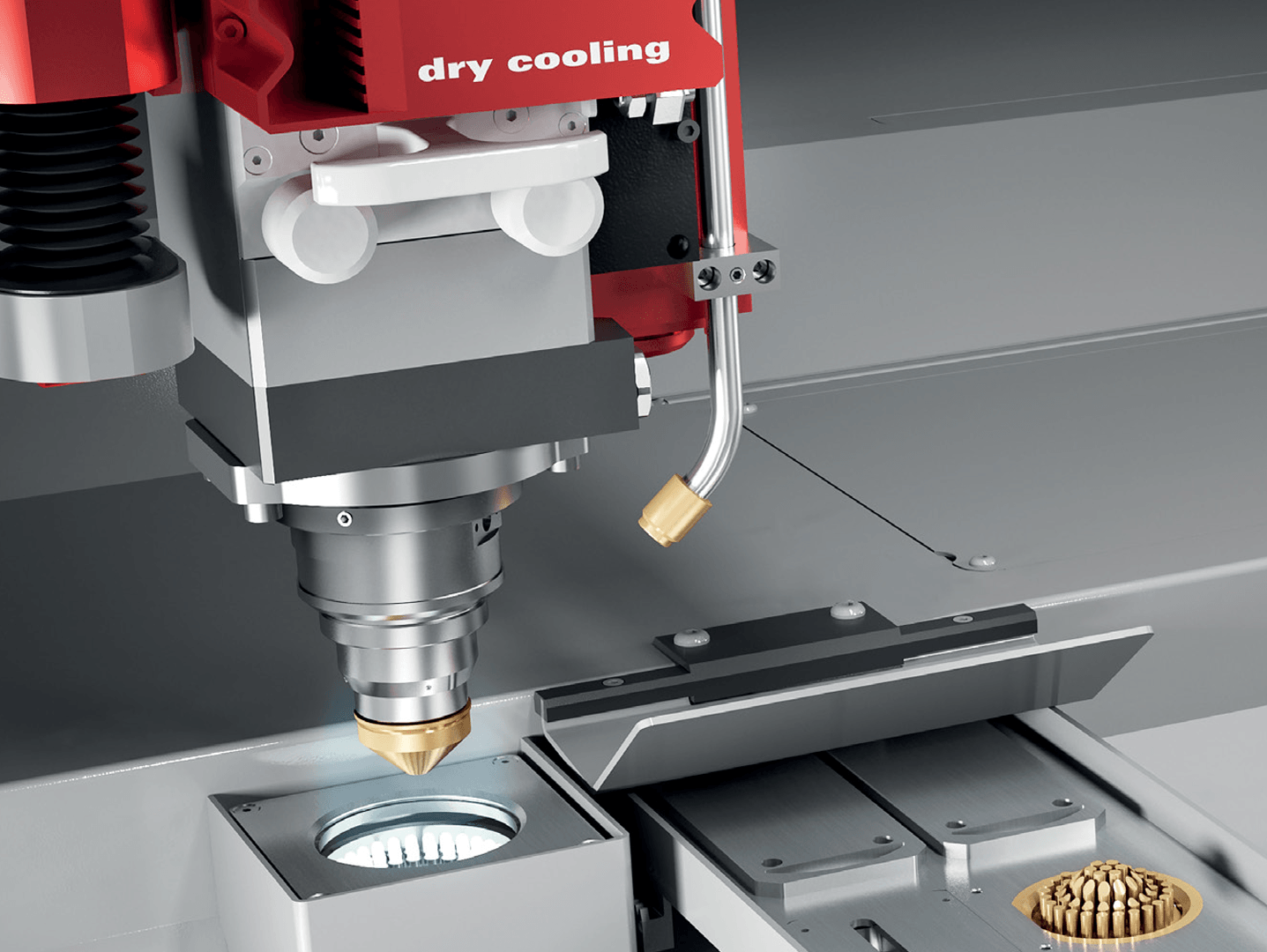

The press brake automatically adapts re-tooling and tool management according to what needs to be produced, with its ATA, MVM and AU-TO devices, thus extending its flexibility and autonomy. The integrated adaptive technologies make the system intelligent, eliminating scrap and corrections, while the press brake integrated into robotized bending cells extends availability, with significant impacts on both precision and repeatability.

Eliminating activities with low added value

Taiichi Ohno was the first to relate efficiency improvement with waste elimination, exploiting 100% of the production capacity of the available systems. Considering that our production capacity corresponds to the sum of work and waste, the second level at which automation impacts production is that of its ability to reduce, if not fully eliminate, redundant activities or those with low added value which typically occur upstream and downstream of individual systems for preparating, feeding and connecting.

In substance: optimizing individual production phases has progressively increased the performance efficiency of machine tools for sheet metal working. Automatic cutting, forming and panel bending systems have become extremely quick and productive, shifting the problem of efficiency to the loading and unloading phases which, increasingly often, risk becoming authentic bottlenecks. In production contexts marked by low volumes and rapid production changeovers, connecting automatic loading/unloading devices to the systems is a winning strategy for recovering efficiency.

Salvagnini responds to this need with a wide, modular range of automations, able to configure each system differently to meet different production needs. The whole range was recently updated, not only to fit practically all layout and configuration needs, but above all to the need to reduce loading/unloading times even further. While the higher performance of the systems has reduced cutting times, Salvagnini automation has naturally evolved.

This includes:

• automatic loading/unloading and sorting devices, coupled to a store, which are an enabling factor for increasing the autonomy and efficiency of individual cutting and punching systems: these ensure that different materials and thicknesses are always available for just-in-time jobs, reducing sheet metal feeding waiting times and the risk of error or damage to the material due to human intervention;

• automatic loading devices, which are also decisive for bending semi-finished parts, as they ensure that the machine is fed at a frequency consistent with the production speed, canceling waiting times for sheet metal feeding;

• robotized unloading devices, which ensure that the panel bender is immediately available for the next job after completing the previous one: this automation not only eliminates waiting times linked to the outgoing sheet metal, but also recovers efficiency in subsequent phases of the process, such as robotized welding, which benefits from the precision offered by automatic bending and robotized stacking;

• intermediate automation devices – transfer conveyors, turnover units, etc. – that minimize and balance material transfer times from one workstation to the next, both physically integrating several machines in a single FMS, as in the case of the S4+P4 line, and keeping them independent even when included in a flexible production cell;

• software solutions facilitating the production process by reducing errors and operator intervention times even without large physical devices, lowering the entry barrier into the world of smart manufacturing.

Process management and optimization

Extending the vision to managing and optimizing the process as a whole, obliges us to talk of digital transformation and Industry 4.0, which for the last few years have been some of the hottest industrial topics. A widespread view often reduces Industry 4.0 to the mere integration of the ERP system and the receipt of machine feedback, when in fact this is a minimum requirement, the first step to be tackled, which must then become an enabling factor for solving real problems, simplifying everyday work, and helping companies to grow.

Salvagnini has been concretely tackling this issue since 1993, when it launched the first OPS, the modular software for managing production. OPS receives the production list from the factory information management system in real-time, and delivers an updated version to the programmer. It provides support for the programmer's activities by defining the priorities, automatically generating the machine programs, and sending them to the workshop. It checks the availability of raw materials or semi-finished parts and generates feedback to the factory information management system, updating it in real time, part by part. It can make autonomous decisions according to a production logic – or according to a multiple mix of production logics – designed to meet the needs of the customer and transformed into an algorithm. It integrates labeling, traceability, and store management upstream and downstream of the cutting, punching, and bending activities. It therefore increases the efficiency of the whole production process, extending its effects beyond the factory boundaries and throughout the whole supply chain.

For Salvagnini, that’s what digitalization is all about: making available solutions that are easy to use, in order to focus on control, production process optimization and the elimination of all those often invisible downtimes that undermine the efficiency and competitive performance of companies. It is a fundamental support for managing dynamic, complex productions in today’s industrial scenario.

A vision of the future

There is no point in focusing on extremely high-performing technologies without managing the bottlenecks upstream and downstream of production. Investing to reduce the cycle times of an individual production phase by a few seconds offers no real advantage if the re-tooling times of these technologies cancel out the efficiency regained by the performance of the new system, if this regained efficiency is lost in the intermediate phases between the individual workstations, or if it is canceled out by a burdensome process filled with redundancy, delay and inefficiency.

Salvagnini proposes to replace this purely quantitative approach that focuses only on productivity with another that combines both quantity and quality, shifting from the idea of production capacity to that of production control, where efficiency – and therefore productivity – can be regained. To fully exploit the benefits assured by flexible automation.

CONTACT US

Leave us your info and we will get back to you.

Contact Us

We will get back to you as soon as possible

Please try again later

Check out our additional articles!

AVS

All the benefits of artificial vision

GOING GREEN

Panel bending is green at last, with Salvagnini

Flexible Automation

Automation according to Salvagnini

Digital Jobshops

Upstream from the workshop: increasing programming efficiency

salvagnini america inc.

27 Bicentennial Court

Hamilton, Ohio 45015 USA

513-874-8284

info@salvagnini.com

Salvagnini America Inc,