Be Our Guest!

SEPTEMBER 13th - 16th in Chicago!

THE COUNTDOWN IS ON!

Stop by and say hello!

FABTECH is where the metal forming, fabricating, welding and finishing community comes together to see what's new and what's next. It's where connections are made and where deals get done. Where you can experience interactive exhibits, learn from expert-led education and network with peers.

Click Here for more info about FabTech

ON DISPLAY BOOTH A2950

NEW!

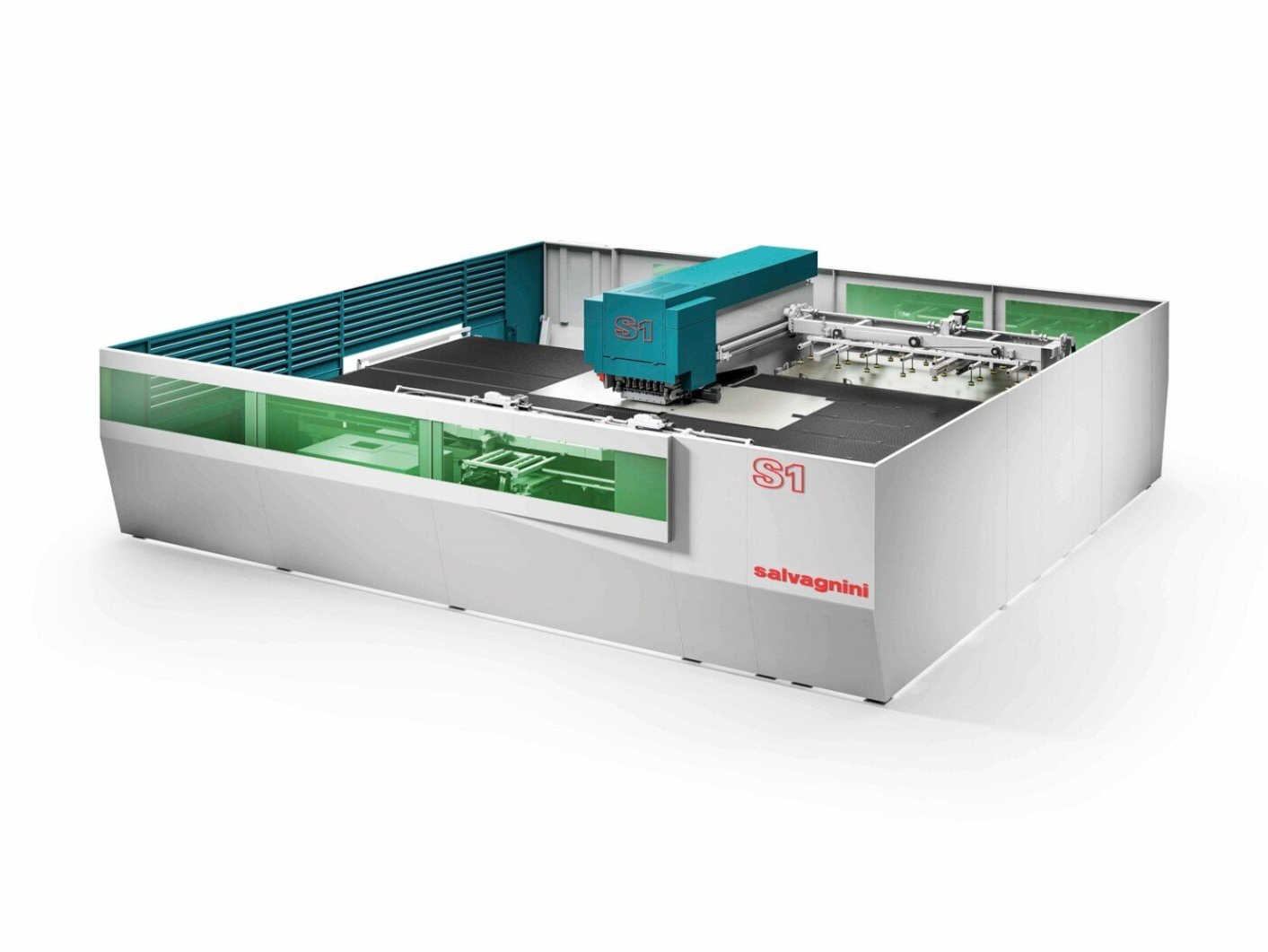

S1 HYBRID

PUNCHING MACHINE

S1 implements innovative and original elements, that make it a solution with a wider range of applications, that goes beyond common similar technology and is unique in the market.

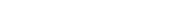

B3 AU-TO

4.0 PRESS BRAKE

The adaptive press brake—the B3 is designed by combining the features and benefits of electric and hydraulic press brakes with Salvagnini’s in-depth knowledge of automation, software, mechanics and electronics.

NEW!

S1 HYBRID PUNCHING MACHINE

- SIMPLICITY: Automatic parameter modulation

- ERGONOMIC DESIGN: Airplane Structure

- VERSATILITY: Single-optic head cooled without gas

- CONFIGURABILITY: Modular automation

- QUALITY: Smart process solutions

- FLEXIBLE AUTOMATION: Precise & unmanned operations

- SAFETY: Class 1 machine

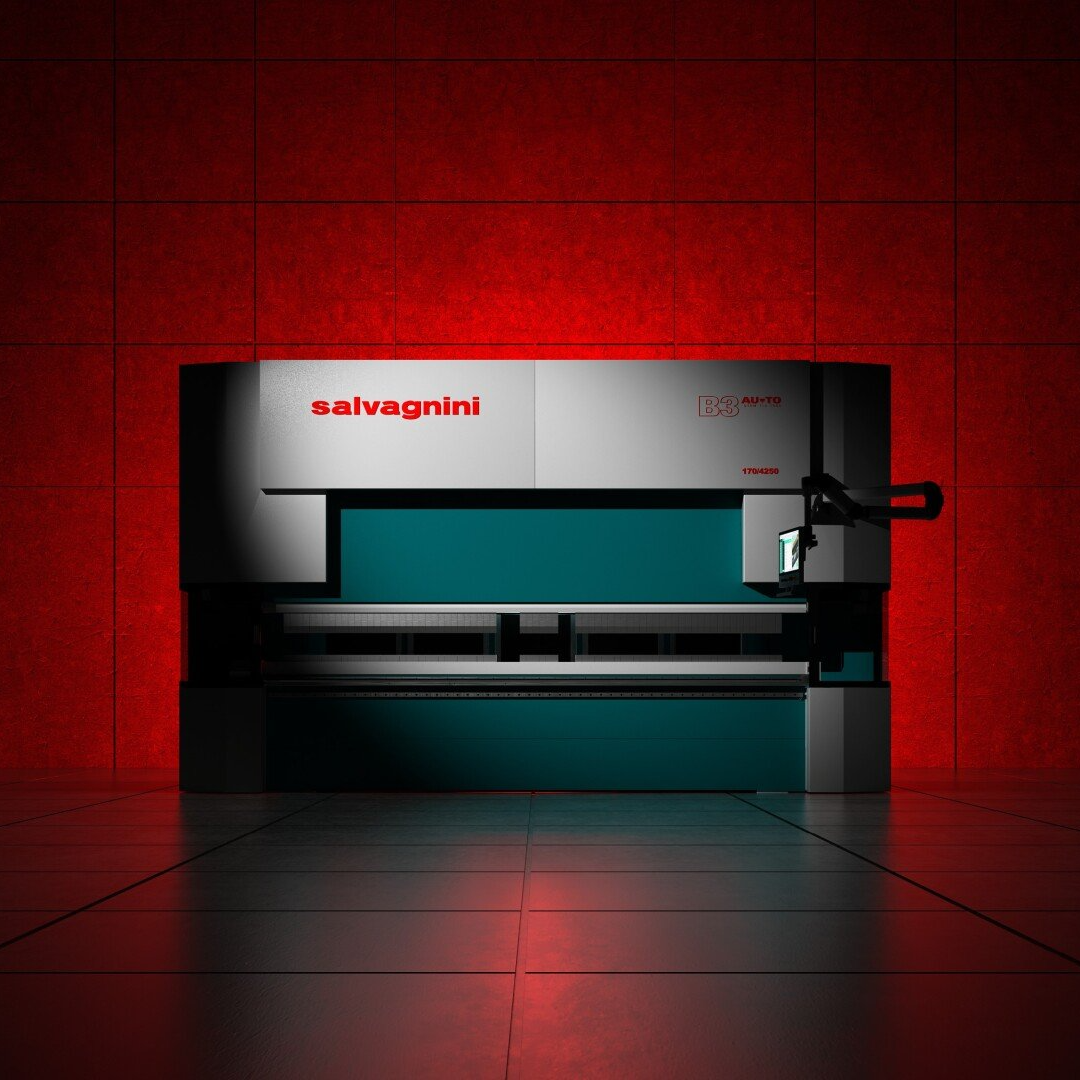

NEW!

P2 LEAN WITH CUT FEATURE

COMPACT PANEL BENDER

- FLEXIBLE: Diversified production, 27 to 11 gage thickness

- PRODUCTIVE: Universal bending tool and no set-up time

- SMART: Adaptive technology, quality, zero scrap.

- SAFE: Totally automatic manipulation in cycle.

- SIMPLE: Adaptive technology & guaranteed quality (MAC 2.0)

- SUSTAINABLE: Reduced consumption (5 kW)

- VERSATILE: Customized solution to produce parts, pieces & panels

ON DISPLAY!

B3 AU-TO 4.0 PRESS BRAKE

- KITABLE: Unique technical solutions (ATA, MVM) combine the productivity and flexibility for batches, single parts or kits.

- 4.0 CONNECTED: The proprietary LINKS, VALUES and OPS software allow seamless communication between the system and all departments.

- MAC 2.0 READY: Integrated adaptive technologies (S-CROWNING, AMS, TFC) make the system smart, allow zero scrap, do not require corrections.

- KINETIC: The architecture and the embedded solutions (Direct Drive, KERS, LSB) are designed to respect both man and the environment.

FEATURING OUR AUTOMATION PARTNERS:

Modula is a leading manufacturer of automated storage solutions, designed to optimize space and improve picking and storage operations for any industrial sector or environment.

Schnelldorfer CORNERWELD seam welding machines were designed specifically to eliminate the need for costly grinding, finishing, and blending, required after welding fabricated bent corners.

https://www.schnelldorfer-maschinenbau.de/en/

#FABTECH2022

SEE YOU THERE!

September 13-16, 2021 at McCormick Place in Chicago, Illinois

salvagnini america inc.

27 Bicentennial Court

Hamilton, Ohio 45015 USA

513-874-8284

info@salvagnini.com

Salvagnini America Inc,