#1 IN PANEL BENDERS

IN THE WORLD

Unlock the Power of Pro-level Panel Bending

Industry Leading Customization with Our Flexible Sheet Metal Panel Benders

The Panel Bender Benefits

Universal Bending Tool

- Versatility: The universal bending tool is a highly versatile tool that can be used to create a wide range of shapes, including straight bends, curved bends, and complex shapes. This feature allows for greater flexibility in production and reduces the need for multiple tools.

- Interchangeability: The universal bending tool is designed to be easily interchangeable with other tools, which reduces setup time and increases flexibility in production. This feature allows for faster tool changes and reduces downtime between batches.

- Precision: The universal bending tool is designed to achieve high precision and accuracy in bending and forming metal sheets. This feature ensures that the final product meets the required specifications and reduces the need for rework.

- Reduced costs: The universal bending tool is a cost-effective solution for bending and forming metal sheets. Its versatility and interchangeability reduce the need for multiple tools, which reduces tooling costs. Its precision reduces the need for rework, which reduces material costs.

Consistent Quality

Using our proprietary software, MAC3.0 , reduces angle/bend and box dimension, fluctuations duet o material variations within its material class. It guarantees high bending quality when bending metal sheets with same material but different material scale Kσ.

- Proprietary algorithm managing tools path.

- Guarantees exact and constant bending movements.

- Reduces scrap.

- Makes machine reliable.

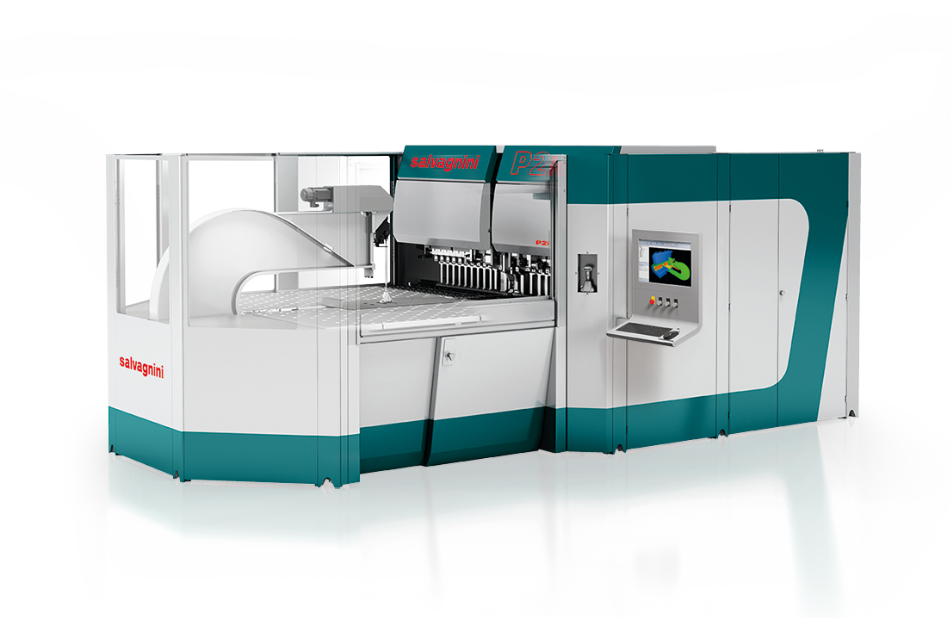

Flexible Automation

Our manufacturing system is designed to be adaptable and flexible to changing production needs. It can be easily reconfigured to produce different products or parts without requiring significant changes to the production process.

- FLEXIBLE: Universal tools

- PRODUCTIVE: Automatic set-up in masked time.

- SMART: Zero scrap and consistent quality thanks to MAC 3.0

- SIMPLE: Intuitive and easy programming software

- REACTIVE: Extensive modularity to allow the machine working in Factory 4.0

- VERSATILE: Custom solution to cut profile or bend articulated parts

- AVAILABLE: Widest range of available models

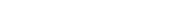

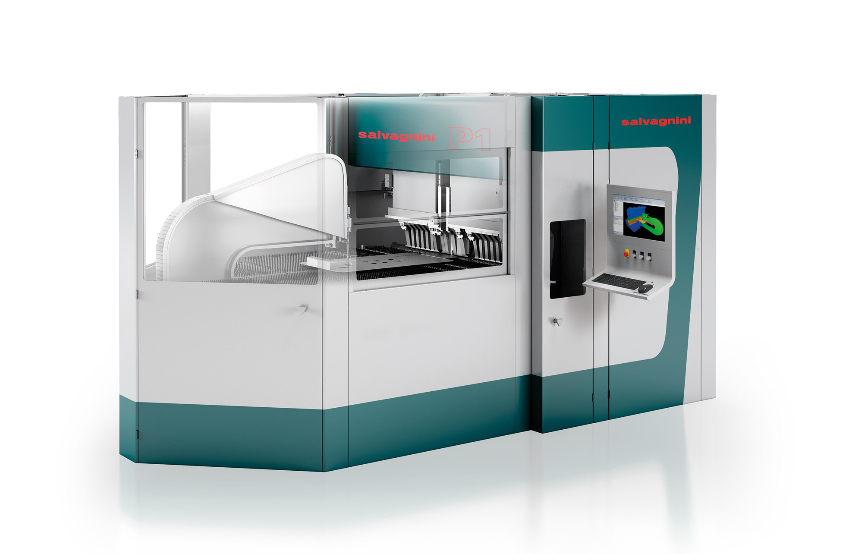

The automatic, flexible bending solution.

Sheet metal panel benders are smart manufacturing tools, invented by Guido Salvagnini in 1977, designed for flexible and automatic production of sheet metal panels starting from punched blanks without retooling or operator intervention.

Salvagnini is largest panel bending manufacturing plant in Europe, with over 40 years of experience. We are an authority on “Panel Bending 4.0”, a flexible process the industry has never seen before—whose application boundaries are extended to sectors and environments that have always been considered poorly suited to this technology.

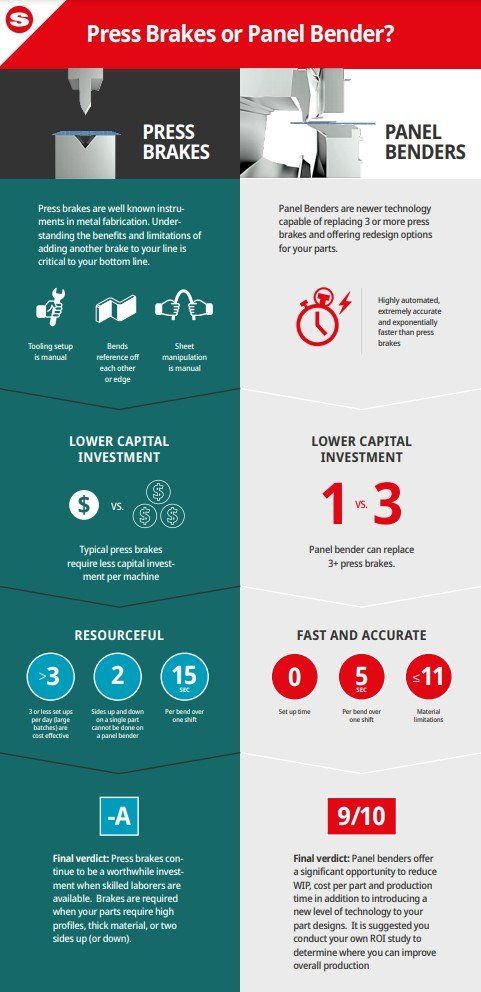

Press Brakes or Panel Bender?

Adding a panel bender to your operation is an excellent way to alleviate pressure on the press brakes, it frees up skilled labor to concentrate on specialty items and opens up new part design efficiencies.

salvagnini america inc.

27 Bicentennial Court

Hamilton, Ohio 45015 USA

513-874-8284

info@salvagnini.com

Salvagnini America Inc,